When it comes to controlling flow inside pipelines, engineers compare gate valves, butterfly valves, and ball valves. Of these three, ball valves are superior for a simple reason: they stop oncoming flow instantly, seal perfectly, and withstand challenging industrial conditions for longer.

This is the reason why industries across India continue to rely on products supplied by every major ball valve manufacturer in Ahmedabad and other industrial hubs.

Whether you manage a water system, a chemical processing plant, a gas line, or an air conditioning system, knowing the operation of a ball valve will help you choose the right valve for both safety and optimal operation.

What Is a Ball Valve?

A ball valve is a quarter-turn shut-off valve that controls the flow of fluid or gas using a rotating ball with a hole drilled through its center. When the hole is aligned with the pipe, the flow passes through without any resistance. When the ball is turned 90 degrees, the hard part prevents the flow from going through immediately.

This simple system brings about three important advantages:

- Fast operations

- Perfect Sealing

- Durability

These reasons are sufficient to justify the presence of Indian ball valve manufacturers in sectors like oil and gas, water treatment, pharmaceuticals, food processing, and power generation.

Main Parts of a Ball Valve

All ball valves have similar internal structures, as follows:

- Valve body—The external part that encloses all the inner parts and joins the pipeline

- Ball—The hollowed sphere that directs the liquid flow

- Seats—The sealing rings that press the ball closely to prevent any leakage

- Stem—The rod that links the ball with either the handle or the actuator

- Seals and O-rings—Stop leakage at the stem and body junction

The simplicity of this design is what gives ball valves their dependable performance under pressure.

How a Ball Valve Works

Using the ball Valve is straightforward and can be easily recognized:

- Open position – The handle is parallel to the pipe. The flow path coincides with the ball’s hole, and the fluid flows without hindrance.

- Closed position—The handle is turned perpendicularly to the pipe. The solid part of the ball obstructs the way, and the flow is cut off entirely.

- The quarter-turn action is the fastest among the majority of valves and cuts down the chances of wrong positioning that may cause system damage.

Manual and Actuated Ball Valves

There are two major categories that ball valves can be classified into:

Manual Ball Valves

This category uses a lever handle for its operation; it is appropriate for low-cycle systems and locations where human access is easy. Manual valves are less costly and are found in plumbing, utility, and minor industrial setups as a common application.

Electric Ball Valves

An electric actuator is used to open and close the valve automatically. They can be controlled together with other systems, and their operation can be done from afar. Electric ball valves are used in HVAC, water automation, and industrial process control.

Pneumatic Ball Valves

The operation of these valves is done using compressed air. They give a quick reaction and can be used in dangerous places where electrical sparks are prohibited. That is the reason why they are widely used in refineries and chemical plants.

2-Way and 3-Way Ball Valves

- 2-Way Ball Valves: An inlet and an outlet are present, and they serve standard on and off flow control.

- 3-Way Ball Valves: Three ports are present, and either an L-port or T-port bore is used. The L-port diverts the flow between the two directions. The T-port enables the mixing or splitting of the flow in three directions. Most ball valve manufacturers in India offer both kinds for the flexibility of industrial processes.

Ball Valve Materials and Their Uses

Material selection is based on pressure, temperature, and media type:

- Brass – Plumbing and low-pressure applications

- Stainless steel – Chemicals, high temperatures, corrosive media

- Plastic (PVC, CPVC) – Chemical handling and irrigation

- Cast iron – High-pressure industrial systems

Seals commonly use PTFE, EPDM, FKM, or metal, depending on temperature and chemical exposure.

Connection Types for Ball Valves

Ball valve connection types are as follows:

- Screw-on ends for smaller pipelines

- Flanged ends for large industrial pipes

- Welded ends for permanent installations

- True union ends for maintenance-friendly systems

- Hose connectors for low-pressure flexible lines

A reliable ball valve manufacturer in Ahmedabad typically supplies most of these connection options under one roof.

Full Port vs Standard Port Ball Valves

- Full port – The pipe diameter is equal to the bore diameter. There is a minimum pressure drop. It is ideal for pigging systems.

- Standard port – The bore is slightly smaller than that of the full port. It causes a minor pressure loss. It is more compact and cost-effective. Process industries usually opt for full-port valves when flow performance is important.

Reasons for Ball Valves to Prevail in Indian Industries

The growing demand for efficient flow control systems is unstoppable with the increase in infrastructure, chemicals, pharmaceuticals, and power. This has made all the leading ball valve firms in Ahmedabad, and also the big Indian ball valve factories, for both domestic and export markets.

Ball valves are still the preferred choice when it comes to the safe isolation of flow in applications such as bulk water supply systems, fuel pipelines, and pharmaceutical cleanrooms.

Conclusion

Grasping the operation principle of a ball valve enables engineers and purchasers to choose the correct setup for safety and productivity. Ball valves, ranging from simple manual shut-off to fully automated pneumatic controls, offer unmatched reliability in modern piping systems.

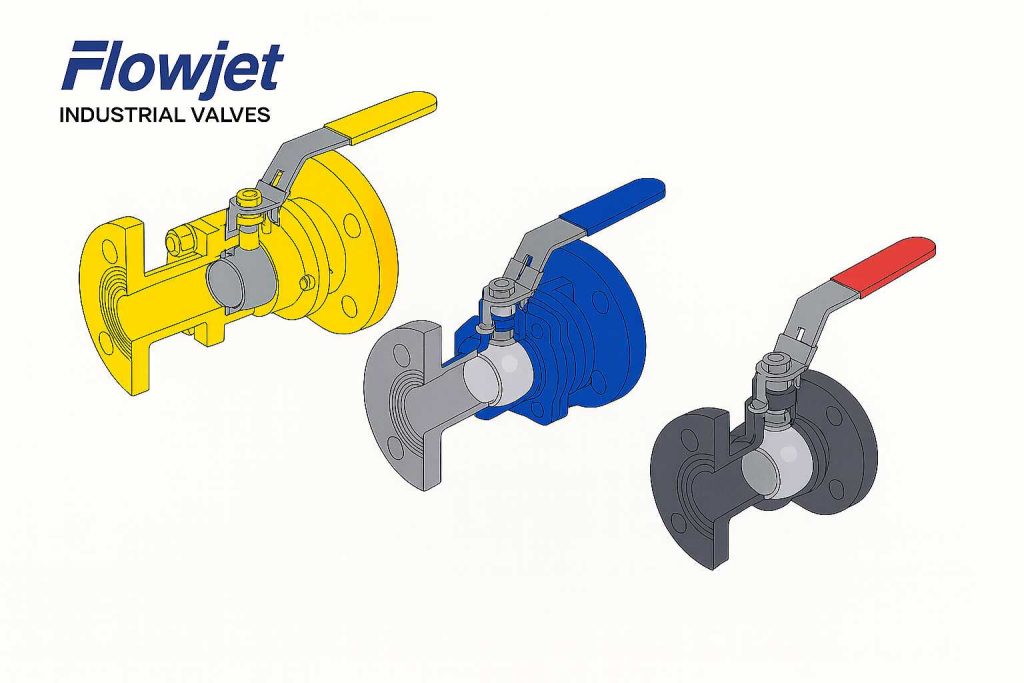

If you are looking for industrial flow control products, then Flowjet Valves is the best ball valve manufacturer in Ahmedabad, presenting the most suitable choices. Our ball valves are designed with high precision and are certified for Indian operating conditions across the entire spectrum of pressure, temperature, and chemical resistance.

Feel the quality of Flowjet Industrial Valves and protect your installations with the current winning ball valves in accuracy, safety, and prolonged trustworthiness.