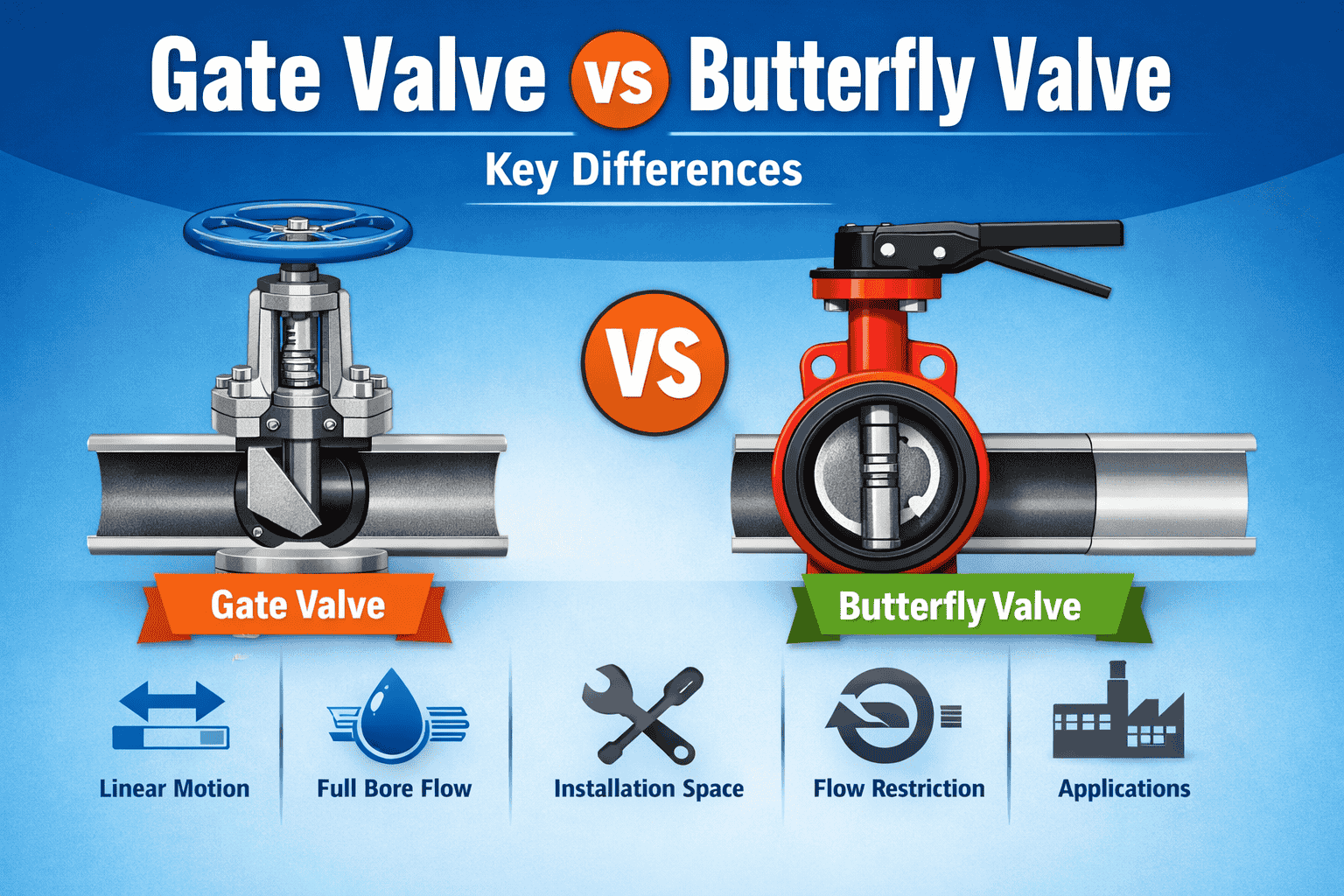

In industrial fluid control applications, the selection of the right valve directly impacts performance, safety, and operating expenses. Among the various kinds of valves used in industries, gate valves and butterfly valves are two of the most frequently employed ones. Both are used to regulate the flow of fluids and gases, but there are considerable differences in their physical structure, method of operation, and suitable applications. Understanding these differences helps engineers, buyers, and operators make informed decisions.

This guide explains gate valve vs butterfly valve differences in a very practical way, from design to cost, hence making it easier for you to choose the appropriate valve for your system.

What Is a Gate Valve

A gate valve is a type of valve that uses a solid gate to control the flow of liquid or gas through the valve body by either lifting or lowering it. When the gate moves vertically, the fluid can flow through the valve at a full rate; on the other hand, when it is closed, the fluid is completely cut off. This design makes gate valves ideal for isolation purposes.

Gate valves are found in applications where a straight-line flow and minimal pressure loss are required. Because the gate fully retracts from the flow path, turbulence remains low. This is the main reason why many industries like to buy from a trustworthy gate valve manufacturer in Ahmedabad when dealing with high-pressure pipelines.

A gate valve takes time to operate due to its multi-turn mechanism, which prevents sudden pressure surges and consequently lowers the risk of water hammer.

What Is a Butterfly Valve

A butterfly valve uses a rotating disc mounted on a central shaft. The valve is opened or closed simply by turning the disc by 90 degrees. This quarter-turn method enables quick and easy automation, along with the quick response feature. Butterfly valves are small, lightweight, and occupy less space compared to other types of valves.

They work effectively in large pipe systems where fast operation is vital. Many butterfly valve manufacturers offer valves that serve both throttling and isolation purposes. Even though the valve is fully opened, there is still some pressure loss due to the disc being in the flow path. However, fast operation and cost efficiency are the reasons why butterfly valves are widely used in various industrial sectors.

Structural Design Differences

Structural Design Differences: Gate valves are made up of a body, bonnet, stem, and gate. Types vary to include wedge gate, knife gate, and parallel slide. The design is all about sealing ability and longevity.

Butterfly valves take the form of an uncomplicated construction of a disc, stem, seat, and body. Designs vary with offset types like concentric, double offset, and triple offset, all of which enhance sealing and reduce wear.

Industries frequently seek the advice of a reputable industrial valves manufacturer to make sure the appropriate gate design is selected for specific pressure applications.

Working Mechanism Comparison

Gate valves use linear motion to function. The gate goes up completely out of the flow path, allowing unrestricted movement of the media. Therefore, they can be employed in systems that need the full bore flow.

Butterfly valves use rotational motion to work. The disk rotates to control or cut off the flow. Because of this operation, butterfly valves are faster in their response and are ideal for applications with frequent operation.

Automation preferences for butterfly valves come from their easy integration with actuators.

Application Suitability

Gate valves are most suitable for pipelines where valves remain in one position for a long period of time. They are apt for high-pressure systems and applications where sealing is the most stringent requirement.

Butterfly valves are the ones that can be used in applications that involve flow regulation, frequent opening and closing, or very tight limitations of installation space. They are widely used in water distribution, HVAC, fire protection, and chemical processing.

Butterfly valves are more cost-effective and less labor-intensive for large pipeline installations. This explains why butterfly valve manufacturers supply them in large quantities to the municipal and industrial sectors.

Pressure Handling and Flow Control

Gate valves are suitable for the highest pressures, and their leakage rate is practically zero if they are completely closed. They are also applicable in bi-directional flow conditions.

Butterfly valves are usually able to manage the pressure from a moderate to high range, depending on the type of design. Triple-offset butterfly valves perform constantly in the most challenging conditions while still providing a tight shut-off.

For perfect pressure handling, industries select gate valves from an experienced gate valve manufacturer in Ahmedabad as they prioritize pressure endurance and sealing performance.

Cost and Installation Factors

Gate valves may be cost-effective in smaller sizes. Still, as pipeline diameter increases, gate valves become heavier and more expensive.

Butterfly valves are still very economical even at large sizes because of their small size and little material consumption. Less room and support structure are required for installation.

The cost-benefit is the main factor that leads many industries to use butterfly valves.

Maintenance and Service Life

Gate valves are very low-maintenance when operated properly. But the partial opening might lead to the destruction of the seats and the gate.

Butterfly valves, on the other hand, have simpler maintenance since they are made of fewer parts. Their discs in an abrasive medium may suffer a little bit of wear, but contemporary productions do this through the use of better materials.

At Flowjet Valves, valve designs are mainly influenced by the factors of durability, ease of use, and performance suitable for specific applications to guarantee a long service life.

Conclusion

The decision of whether to use a gate valve or a butterfly valve is influenced by the pressure requirements, space availability, frequency of operation, and cost considerations. In high-pressure systems, gate valves with their exceptional sealing and low flow resistance can be used for isolation. While butterfly valves are characterized by their speedy operation, compactness, and cost-effectiveness, they are also ideal for large pipes and flow control.

The choice of the right valve industrial valves manufacturer becomes crucial as the industries keep advancing. Flowjet Valves brings engineered solutions that are a perfect mix of performance, reliability, and long-term value.

Visit Flowjet Valves and view our gate valves and butterfly valves range to select control solutions designed for industries.